Kogel Bearings are built for Everyday Racing. Read all about it in this related blog post. It will explain why bearings with the very lowest friction are not the best for most athletes.

If you want to use your bike(s) for training and racing and prefer not to spend 15 hours per week cleaning and servicing, building your bearings with a low friction grease works best.

Your race-day preparation requires a little break-in, but after that your setup strikes the perfect balance between low friction and durability. This is very similar to breaking in a pair of shoes.

Extreme Efficiency

I remember Nike released the Mayfly in 2003. A pair of running shoes that were lighter than anything on the market: parachute fabric top, minimal arch support and lightweight foam soles that were built to lose their bounce after 45km of running.

That’s right: these shoes were designed to be the ultimate running shoes for one marathon. They were bright yellow and had a box printed on them, so you could write your finish time before hanging them in your trophy case.

Similar logic applies to bike set up. Derailleur pulley wheels are the fastest rotating components on a bicycle, so reducing drag here is a good starting point. The main sources for friction in a bicycle bearing are the seals and lubrication. Kogel offers cross seals (for best protection) road seals (for lowest friction), which are the easy pick for race day.

Everyday Racing vs ultimate race-day performance

Low-friction lubrication is typically achieved by using a low viscosity oil. Some bearing specific oils have additives in them to reduce friction even further.

The idea is that it is easier for the bearing internals to move on a smooth surface than to battle their way through the thick goop such as a waterproof grease.

Setting up your pulleys for ultimate race-day performance

The short version of prepping your ceramic bearings for race-day performance is:

1. Remove back side of the pulley cage

2. Remove pulleys from derailleur cage

3. Remove pulley cover

4. Remove dust cover

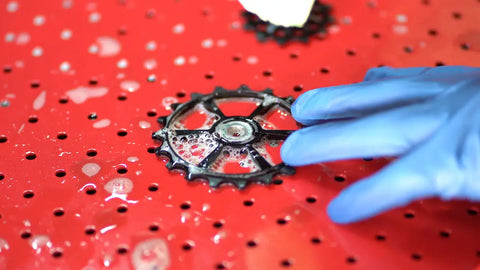

5. Clean old grease and debris from the bearings

6. Blow out any residue with compressed air

7. Apply just a few drops of light oil to lubricate each bearing

8. Replace the seals and cover

9. Reassemble cage

10. Break in your bearings with a short ride - Your warm-up before the race or shaking out the legs before race day is enough to push excess oil aside and leave a thin film on the balls and races.

Protecting bearings for your next race

The process of prepping of your pulleys will make for the fastest possible setup, but it will not last forever. After the race, ride your bike for a week or so, maybe two, but any longer will start premature wear on your bearings.

The good news is this procedure works every single time and can be easily reversed using Low Friction Grease instead of oil for Everyday Racing. Use a fresh coat of oil if your next main event is around right around the corner.