Sram’s introduction of the 12-speed Etap AXS system caught my attention last year. And let’s give credit where credit’s due: it caught EVERYBODY’s attention. This was arguably THE best-coordinated product releases we have seen in our industry.

With that said, the most interesting news to me was not the addition of a twelfth cog to the cassette, but the fact that the additional cog was a 10 tooth, the largest cog available was a 33 tooth and chain rings maxed out at 50 teeth. In a world where cog sizes are getting bigger, Sram decided to shrink their cassettes and chain rings.

AXS Design Benefits

The benefits of smaller chain rings according to Sram all make sense to me: reducing weight, smaller jumps between the gears and a larger range between the lowest and highest gear.

The benefit to larger chain rings and cogs is reduced friction. Chains need to articulate less around a larger wheel. Larger chain rings and cogs also reduce chain tension in the upper half while pedaling.

AXS Design Concerns

Sram’s decision to downsize the entire drive train using smaller cogs bucks the industry trend. In Ironman races and on Tour de France time trial bikes, giant 58-tooth chain rings and oversized derailleur cages are common.

Figure: a 58-tooth chain ring on a TT bike set up for the Tour de France

Reducing the size of the cogs on a cassette and downsizing the chain rings introduces inherent inefficiency.

Real-World Performance Data

I found a few public records of friction tests about chain ring / cog sizes and chain line.

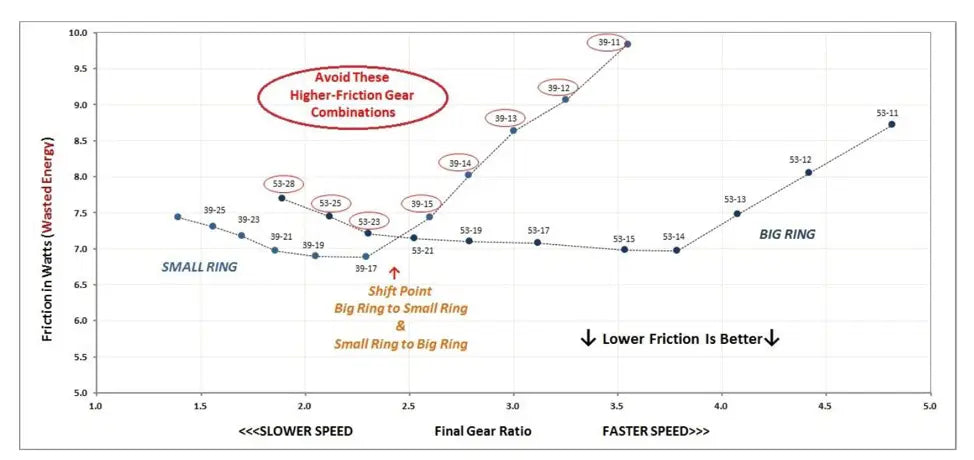

Friction Facts released a report in 2015 about the effects of chain ring size and chain misalignment that shows some interesting results:

** Frictional Losses Due to Chainring Size. Source: Friction Facts report April 7, 2015

Looking at the 53-tooth chain ring curve, it is clear that the 11-tooth cog has a larger friction loss than the 14-tooth. Note how the increase in friction gets progressively worse as the cogs get smaller.

Extrapolating this graphic, I guesstimate a 10-tooth cog would add another 1W of friction loss over the 11-tooth cog.

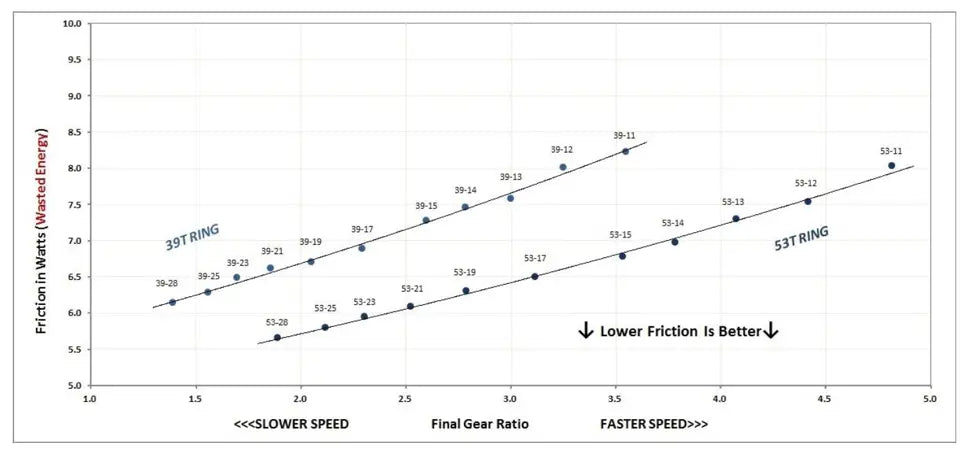

Fun fact: once the drivetrain is set up to exclude the additional friction caused by running imperfect chain line, the results still show that smaller cogs cause higher friction. Extrapolating the graph shows that a 10-tooth cog adds an estimated 0.75W over an 11-tooth cog.

** Frictional Losses Due to Chainring Size (Without Chain Lateral Misalignment). Source: Friction Facts report April 7, 2015

These losses also apply to using smaller chain rings vs larger chain rings. The mid-size option on Etap AXS has a 48-tooth large ring, which should compare to the 52-tooth count found on a standard mid-compact setup.

Velonews published a report in 2019 researching the efficiency losses between a 1x and 2x system, comparing a 48 tooth 1x set up with a 10-tooth small cog to a 53 tooth 2x setup with an 11-tooth small cog.

The total difference in friction loss between the two setups with a very similar gear ratio was 6 Watts. Small cogs and chain line were pointed out as the main reasons for the difference.

How much loss are we talking?

At this point I cannot find any actual data on friction losses caused by the Sram AXS system, but we can see the main ingredients featured in the above tests: smaller chain rings, cogs and a slightly less ideal chain line.

Because the cassette is slightly wider to accommodate the additional gear, it is safe to say that the friction loss is somewhere in between the 1W found in the first paragraph and the 6W found in the 1x vs 2x test on Velonews.

My gut feeling says it is closer to the upper end of the range since all the components are present: smaller chain rings, smaller cogs and affected chain line.

Does Kolossos offset the friction losses?

First and foremost, at Kogel, we’re fans of Sram’s AXS Etap groupset and we absolutely love the simplicity that a 1x drivetrain offers.

The ballpark for friction benefits of running an oversized derailleur cage is in the 2-3 watts range. A safe conclusion is to say that Kolossos will negate some, but not all of the losses.

Keep an eye out for the release of our new Oversized Derailleur Cage later this Spring; you could combine the benefits of Sram’s new AXS Road system while offsetting some of the down sides. Stay tuned.